Understanding Variable Refrigerant Flow Technology

The technology operates through variable speed compressors that adjust refrigerant flow based on real-time demand from individual indoor units. This modulation capability allows the system to operate at partial loads most of the time, significantly reducing energy consumption compared to traditional HVAC systems that cycle on and off at full capacity. Our Commercial Department does offer innovative custom HVAC designs for VRF systems, leveraging our in-house duct designer with Wright Soft energy calculation certification to ensure optimal system sizing and configuration for each unique application.

Key Advantages and Energy Efficiency Benefits

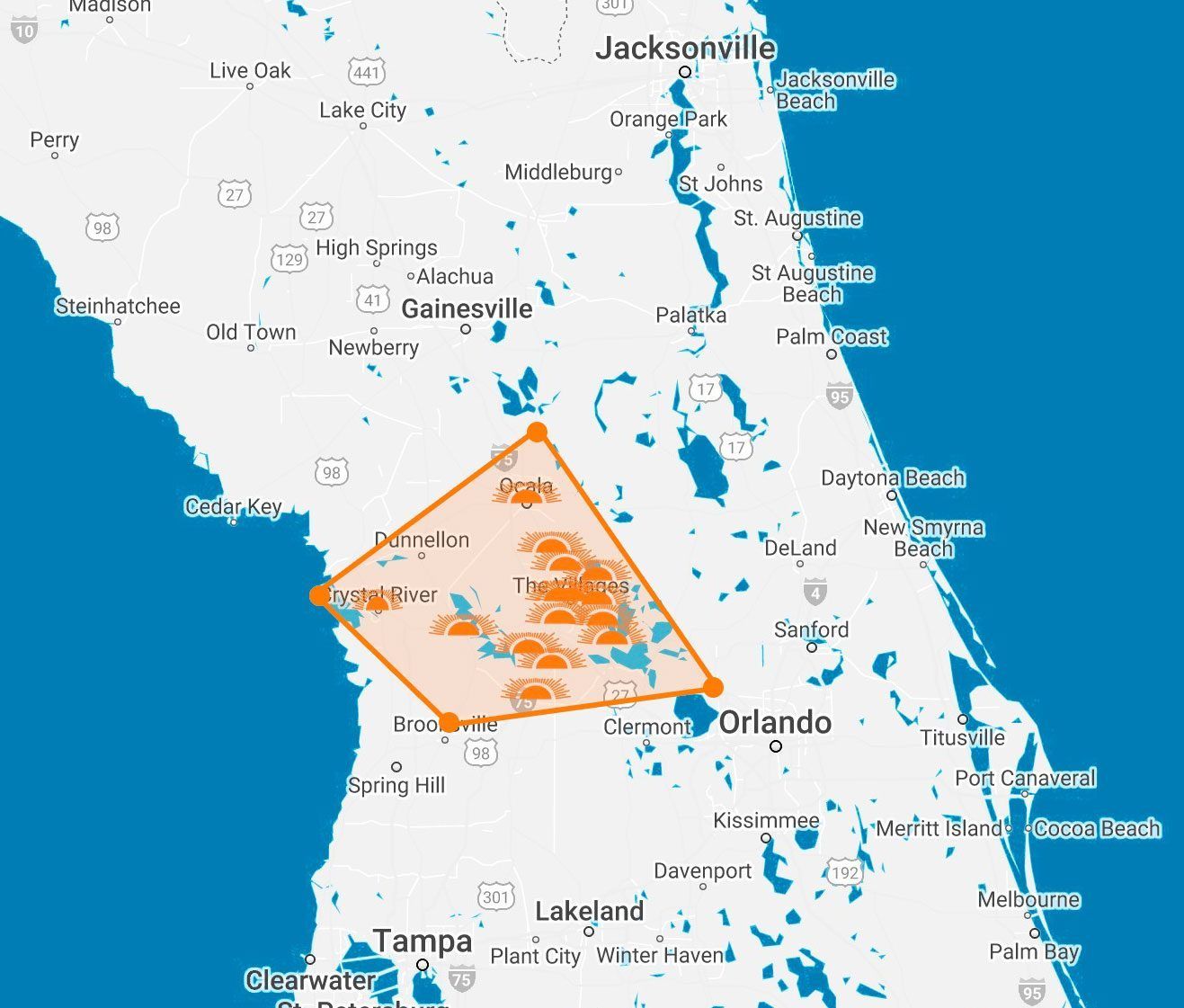

When we install VRF systems throughout Wildwood, Ocala, FL, and the surrounding areas, we consistently observe energy savings ranging from 25% to 50% compared to conventional rooftop units or water-source heat pump systems. These savings stem from several technological advantages inherent to VRF design. The inverter-driven compressors continuously adjust their speed to match the exact cooling or heating load, eliminating the energy waste associated with frequent start-stop cycles. Additionally, the ability to recover heat from zones requiring cooling and redirect it to zones needing heating creates remarkable efficiency gains, particularly during shoulder seasons when buildings experience diverse thermal loads.

The zoning capabilities of VRF systems provide unprecedented comfort control, allowing individual occupants to adjust temperatures in their specific areas without affecting other zones. This personalized comfort approach not only improves occupant satisfaction but also prevents energy waste from conditioning unoccupied spaces. Modern VRF systems incorporate advanced controls that integrate with building automation systems, enabling facility managers to monitor performance, track energy consumption, and implement scheduling strategies that maximize efficiency while maintaining comfort.

Installation Process and Technical Specifications

Installing a VRF system requires careful planning and expertise, which our NATE-certified technicians bring to every project. The process begins with comprehensive load calculations and system design, considering factors such as building orientation, occupancy patterns, and internal heat gains. Refrigerant piping runs can extend up to 1,000 feet with elevation differences of 160 feet between outdoor and indoor units, providing exceptional flexibility in system layout. The piping network uses branch selectors or Y-branches to distribute refrigerant to multiple indoor units, with each connection point requiring precise brazing techniques to ensure leak-free operation.

Indoor unit options include ceiling cassettes, ducted units, wall-mounted systems, and floor-standing models, each suited to specific architectural requirements and aesthetic preferences. Outdoor units range from 6 to 60 tons of capacity, with the ability to connect up to 64 indoor units to a single outdoor unit in some configurations. As a Carrier Factory-Authorized Dealer, we ensure proper refrigerant charging procedures, vacuum testing, and commissioning protocols that validate system performance against design specifications.

Ideal Applications and Market Sectors

VRF systems excel in diverse building types where traditional HVAC approaches face limitations.

- Hotels and hospitality facilities: Individual room control reduces energy costs while maintaining guest comfort

- Office buildings: Open floor plans benefit from flexible zoning that adapts to changing tenant configurations

- Healthcare facilities: Precise temperature control supports critical environmental requirements

- Educational institutions: Quiet operation and individual classroom control enhance learning environments

- High-rise residential buildings: Compact equipment footprints preserve valuable floor space

The modular nature of VRF systems facilitates phased construction projects and building expansions, allowing property owners to add capacity incrementally as needs grow. Family-owned and operated since 1984, we’ve installed VRF systems in retrofits where existing buildings require modernization without extensive structural modifications, as the compact refrigerant piping often fits within existing chase spaces and ceiling cavities.

Maintenance Requirements and Long-term Performance

Proper maintenance ensures VRF systems deliver their promised efficiency and reliability over their 15-to-20-year service life. Our preventative maintenance plans include quarterly filter changes, annual coil cleaning, refrigerant leak testing, and comprehensive system diagnostics using manufacturer-specific service tools. The electronic expansion valves in each indoor unit require periodic calibration to maintain optimal refrigerant flow control. We offer 24/7 emergency repair services for all major HVAC brands with no overtime fees—straight time, all the time, no overtime—ensuring your VRF system receives prompt attention when issues arise.

Regular maintenance extends beyond basic cleaning and inspection, encompassing software updates for control systems, verification of safety devices, and trending analysis to identify potential issues before they impact comfort or efficiency.

Carrier Factory Authorized Dealer

Sun Kool Air Conditioning Inc. is proud to be a Carrier Factory Authorized Dealer, meeting rigorous standards in quality, customer service, and technical expertise.

Carrier President's Award Winner

Recognizing excellence in customer satisfaction, HVAC expertise, and operational excellence